Edible Oil Refining Dewaxing Plant

Dewaxing Plant

Dewaxing Plant

Centrifugal or Traditional Dewaxing is ideal for edible oils with a small amount of Soap Stocks (Only for sunflower oil). This process comprises of a small amount of acid being added to the oil before being fed into a Hydration Tank. The edible oil is then passed through to the first stage of centrifuging followed by cooling down for Crystallization. The wax crystalizes and the oil is passed through to a Maturator. The second stage of centrifuging ensures all the waxes are removed along with any traces of soap. The final process of this stage is drying.

Dewaxing is an important physical process suited for Fats and Oils. A perfectly bleached oil is put through the process of Dewaxing. This process can be executed in one of 2 ways:

Dewaxing with residual soap stock by centrifugation

Dewaxing with residual soap stock by centrifugation Dewaxing by sequential cooling of bleached oil followed by filtration

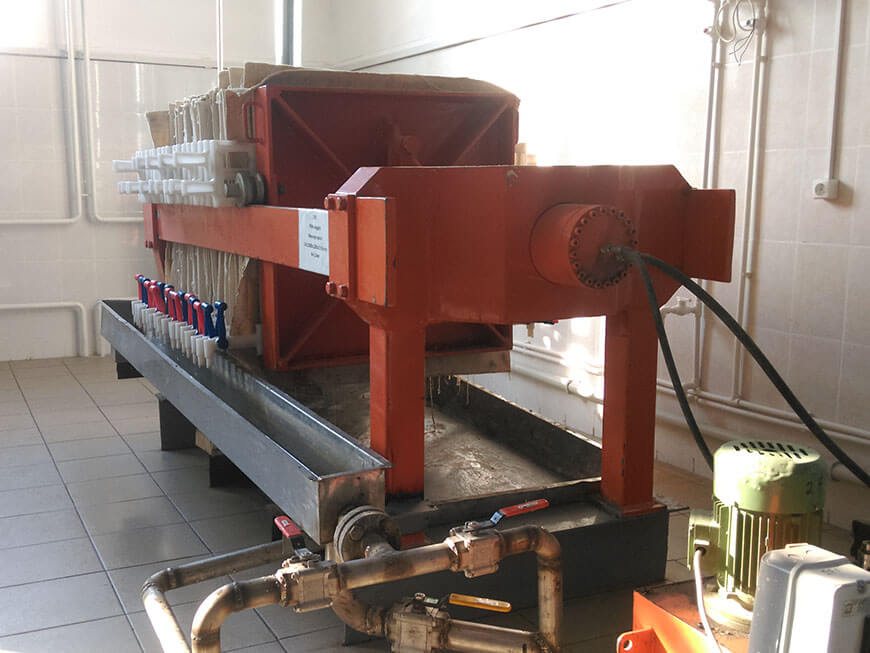

Dewaxing by sequential cooling of bleached oil followed by filtration

The process of centrifugation is comprised of leaving a few parts per million of soap stock during the neutralization process in the oil and cooling in maturator, followed by Filtration and heating of oil. This process generally features lower losses in value compared to simple cooling in crystallizer and filtration.

The process by cooling and Filtration is comprised of sequential cooling of bleached oil and then filtration. This process is easy to undertake however crystallizer design plays a very important role. Muez-Hest boasts of some very innovative and workable Crystallizer designs.

Application:

Sunflower Oil, Rice Bran Oil