Packaging and Distribution

Following refining and potential fractionation, the oil is meticulously filtered, packaged into suitable containers such as bottles, cans, or drums, and then labeled for subsequent distribution to consumers or industrial clients.

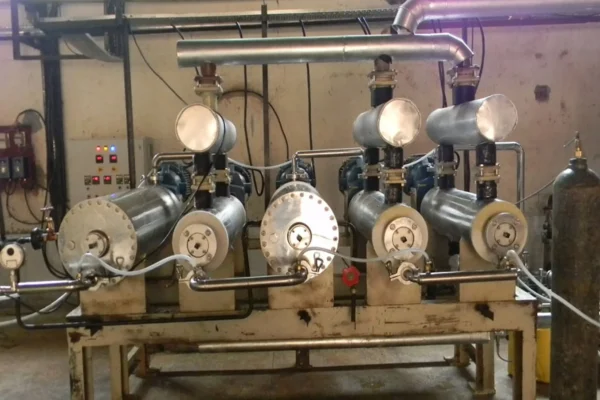

In the case of industrial oils, the manufacturing process may encompass supplementary steps like hydroprocessing, dewaxing, and extra refining phases. These additional stages are tailored to meet the specialized requirements of industrial applications.

It's important to recognize that the specifics of the oil manufacturing process can diverge based on factors such as the oil type, plant capacity, and technological innovations. Furthermore, the growing emphasis on sustainability and environmental concerns is driving the advancement of eco-friendly and highly efficient oil manufacturing processes within these plants.