Edible Oil Refining Dewaxing Plant

Dewaxing Plant

What is a Dewaxing Plant?

The dewaxing process is a crucial step in the refining of vegetable oils and fats, especially those intended for use in food products where clarity and stability at lower temperatures are essential. Dewaxing removes waxes, which are natural components found in oils such as sunflower, corn, and rice bran oils. These waxes can cause cloudiness or haziness in the oil when it is cooled or stored for a longer period, affecting its appearance and stability.

De-waxing is a process that involves cooling oil to a specified temperature where wax solidifies into a slurry while the oil remains in liquid form. The bleached oil is then transferred to the Crystallizer, a specially designed vessel, where it is cooled slowly and steadily to facilitate wax crystallization for easy filtration. This is achieved by gradually lowering the temperature in stages using cold water and then chilled water. After this, some kind of oil is sent to a maturator for maturation, where the temperature is adjusted as needed to ensure proper wax crystal formation. Finally, the oil is filtered using advanced Plate & Frame Filters or Miura Super Filters.

Process of Dewaxing Plant

The dewaxing process in an oil refinery plant is essential for removing waxes from edible oils to improve their clarity and stability, especially in colder temperatures. Here's an overview of the dewaxing process designed for the oil refinery industry:

Initial Cooling:

- The oil is first cooled gradually using cold water to lower its temperature. This step is crucial to prepare the oil for further chilling and to avoid thermal shock, which can affect the quality of the oil.

Further Cooling and Crystallization:

- The oil in crystallizers where it is chilled further to a temperature of 10-15°C.

- This chilling process is managed by a chilling plant equipped with an efficient cooling system which is controlled with smart control valves and temperature sensors.

- The crystallizers are fitted with an agitation mechanism controlled by a variable drive. This allows for controlled and consistent mixing, ensuring even cooling and preventing the breaking of forming wax crystals.

Maturation:

- In some oil cases, after initial crystallization, the oil is transferred to a maturator.

- During maturation, the temperature is carefully adjusted, either increased or decreased as required, to promote the growth and stabilization of wax crystals.

- This step ensures that the wax crystals reach an optimal size for easy removal during filtration.

Filtration:

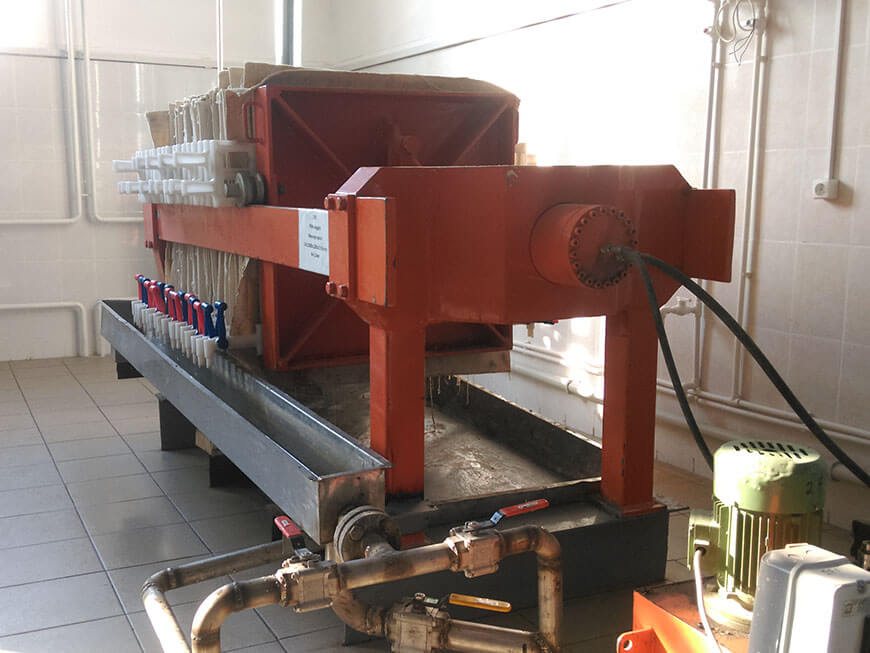

- The matured oil, now containing solidified wax crystals, is passed through advanced filtration systems such as Plate & Frame Filters or Miura Super Filters.

- These filters effectively remove the precipitated waxes from the oil, resulting in a clear and refined final product.

Quality Control and Storage:

- The filtered oil undergoes rigorous quality control tests to ensure it meets the desired specifications.

- The dewaxed oil is then stored at controlled temperatures to maintain its clarity and stability.

- Proper storage conditions ensure that the oil remains free from cloudiness even in colder temperatures.

Packaging:

- The final step involves packaging the dewaxed oil in appropriate containers for distribution.

- The packaging process is conducted in a hygienic environment to preserve the oil's quality and extend its shelf life.

The dewaxing process is critical for oils like sunflower oil (SFO),corn oil and rice bran oil (RBO), which contain significant amounts of wax. By removing these waxes, the oils maintain a sparkling appearance, even in winter temperatures, and have an extended shelf life.

Refinery plants designed by manufacturers like Muez Hest incorporate advanced technology and customized solutions to ensure the dewaxing process is efficient, reliable, and energy-efficient, ultimately delivering high-quality refined oil to consumers with lower losses of oil in wax. Typically, oil becomes cloudy within 5–6 hours, but with proper dewaxing, it remains clear after 24 hours of storage at 0˚C.

Advanced Technology:

- Muez Hest utilizes state-of-the-art technology in their dewaxing plants, ensuring efficient and effective removal of wax from oils. Our crystallizers and filtration systems are designed to maximize cooling effect and nucleation of crystals productivity with highly efficient selection of filters with optimized filter process and maintain the highest quality of refined oil.

Customized Solutions:

- Understanding that each refinery has unique needs, Muez Hest offers tailored solutions that cater to specific requirements. Their team works closely with clients to design and implement dewaxing systems that optimize performance and meet individual production goals.

Proven Expertise:

- With 29 years of experience in the oil refinery industry, Muez Hest has a deep understanding of the dewaxing process and the challenges associated with it. Their expertise ensures reliable and consistent results, enhancing the overall efficiency of the refinery operations.

Quality and Reliability:

- Muez Hest is committed to delivering high-quality machinery that is both reliable and durable. Their dewaxing plants are built using premium materials and are subjected to rigorous quality control measures to ensure long-term performance and minimal downtime.

Energy Efficiency:

- Muez Hest designs its dewaxing plants with energy efficiency in mind. By employing advanced technologies and optimizing process parameters, they help refineries reduce energy consumption and operational costs, contributing to more sustainable operations.

Comprehensive Support:

- From initial consultation and design to installation and after-sales support, Muez Hest provides comprehensive services to ensure the smooth implementation and operation of their dewaxing plants. Their dedicated customer support team is always available to address any issues and provide timely assistance.

Innovative Solutions:

- Muez Hest continuously invests in research and development to bring innovative solutions to the market. Their commitment to innovation ensures that clients benefit from the latest advancements in dewaxing technology, keeping them ahead of the competition.

Global Reach:

- While based in India, Muez Hest has a global presence, serving clients across various countries. Their extensive network allows them to deliver solutions that adhere to international standards and cater to a diverse range of market needs.

Why choose Muez Hest as the Dewaxing Plant Manufacturers In India?

Choosing Muez Hest as your dewaxing plant manufacturer in India offers several advantages for the oil refinery industry. Muez Hest is renowned for its expertise and innovation in the field of oil refining and dewaxing technology. Here's why Muez Hest stands out:

By choosing Muez Hest as your dewaxing plant manufacturer, you can be confident in receiving cutting-edge technology, customized solutions, and exceptional support, all aimed at enhancing the efficiency and quality of your oil refinery operations.